Previously ophthalmic lenses were given a type of soft coating so that they gain additional strength and stand the test of time without breaking away easily. However, this process is almost obsolete now due to the development of another high performing technique known as the hard coating. This type of coating makes lenses so much strong and durable that hardcoat lenses are considered a standard among all other categories of anti reflection coating lenses.

The use of hard coating on lenses gives increased benefits compared to traditional soft coated lenses. Application of a hardcoat on ophthalmic lenses is very smooth process as the layer gets applied evenly on the lenses without any bubble or bumps and is beneficial and workable in even stressful environmental conditions. The hard coating is more consistent as compared to soft coating, and also provides a higher amount of wavelength absorption. In addition to this, hardcoat lenses show great endurance and durability which is rare to find in any other type of coated glass.

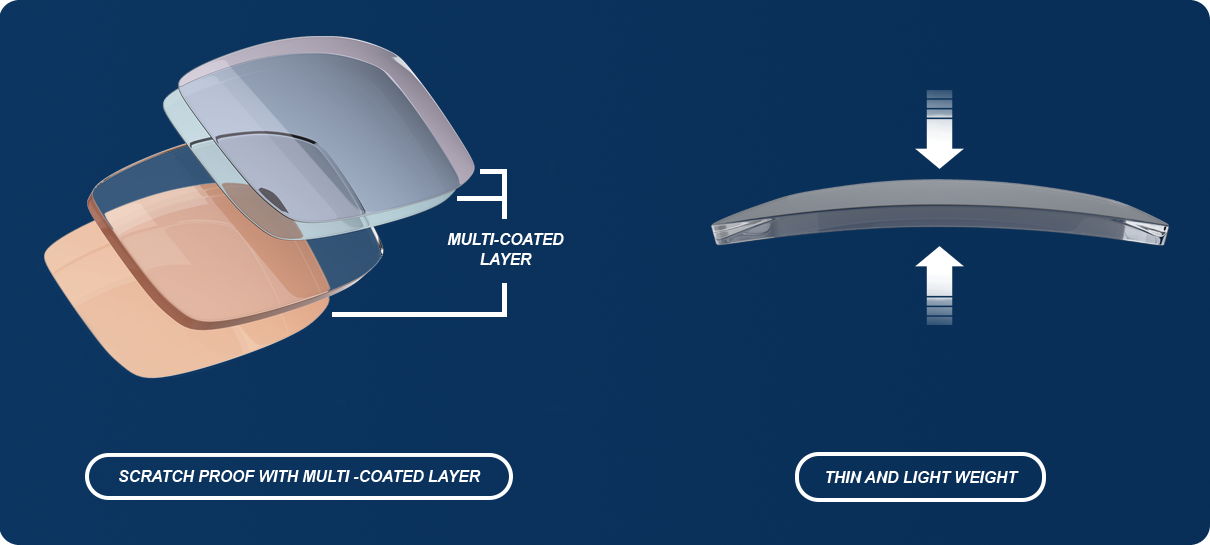

Hardcoat Lens have an anti-reflective coating on them which is an extremely thin layer placed on the surface of a lens. This coating provides the lens with a unique capability of removing any reflections that might normally emanate from the surface of a pair of glasses (both on the front or the back). The hard film is applied in a controlled atmosphere using computer generated programs. This coating is applied evenly on the surface of the lens and is beneficial for use in high stress environmental surroundings. Hardcoat lenses is also known to be helpful in preventing accidents due to vision deflection from glares & ‘halos’ around light sources that may occur at night time.

The two most common type of Hardcoat Lenses are –

Our well-applied Hardcoating or scratch resistant coating provide lenses with high durability and increased longevity. They also help reduce eye strain, eye damage and potential heightened risk of cataracts later in life by blocking up to 100% of UVA/UVB light.